If you’re a NASCAR driver, you’re mainly worried about speed. If you’re a professional baseball player, you’ve got batting averages on the brain. And if you’re a Planner or Scheduler, whether you know it or not, your #1 concern is probably data visibility. (And if you’re the CEO or manager of an organization that has Planners and Schedulers, you should care about data visibility too!).

What’s the big deal with data visibility in my CMMS?

As a Maintenance Planner or Scheduler, the data that you can and can’t see (or can and can’t find) dictates how well you can do your job. Point blank.

Can’t find that WO in a search? It’s gonna be pretty hard to modify it. Can’t see all of the WOs assigned to a particular supervisor who’s no longer in that role? It will be nearly impossible to re-assign them. Unable to filter out your “In Progress” and “Completed” WOs? It’s going to take you way longer to find the approved ones that you need to schedule. Want to find all the WOs allocated to a specific Asset or Location? A good filtering capability is a must!

And if you can’t get the right data on your screen, that’s going to cause problems. Namely:

- Your schedule won’t be optimized: You can only work with what you can see and what you believe is accurate and all encompassing. But if you’re missing some important data, you can’t make the best possible scheduling decisions. A WO that you normally would have scheduled for this week doesn’t make it in the schedule because you didn’t know it existed. Or let’s say there are two WOs that could have been scheduled on the same day to reduce travel time… but you only saw one. That’s a lost opportunity to create greater efficiency for the maintenance team.

- Your maintenance tech’s wrench time might not be at its best: If you’re schedule’s not optimized, then in all likelihood, the wrench time of your techs won’t be either. And since wrench time means more value per maintenance dollar spent, it essentially adds up to wasted time and wasted money. It may seem small, but a little thing like one work order not appearing when you need it can lead to some major real-world inefficiency out in the field.

- You’re going to spend way longer scheduling than necessary: When you can’t trust your data, that means extra work on your part. You probably have workarounds that you go through to try to make sure you haven’t missed anything – not to mention, you’re probably spending way more time scrolling through irrelevant data, looking for relevant data. All this adds up to less time you can spend working on other priorities.

- Your backlog might grow: If you can’t make strategic scheduling decisions, it’s unlikely that the maintenance team is going to be able to keep up with the ever-increasing work. This means one thing: an expanding backlog. And as Break Outs increase and WOs aren’t completed on time, tensions rise, assets break down, and the whole of your organization, whether you’re a utility, a manufacturer, a college/university, a refinery, etc. suffers as a result.

- Your performance might take a hit: In some workplaces, the Planning and Scheduling team is evaluated on metrics of the Maintenance team’s completed work. Bogged down by clutter, the chances that you won’t meet your goals are higher – and this could potentially have serious consequences for your department or contract. I’d much rather be in a position of consistently outperforming the metrics – and to do that, you need to cut through the noise to see only what’s relevant to your work at that time.

How to use sorting, grouping and filtering to cut clutter and schedule better

On any given day, you might need to be able to find WOs based on:

- Required Crafts

- Supervisor and/or Lead

- Assigned Labor

- Status

- Work Type

- Priority

- Location

- Asset Tag or some other attribute

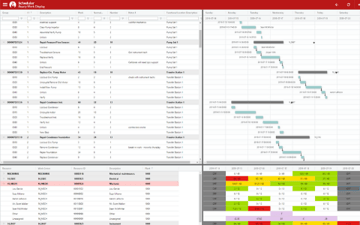

That’s why, in my opinion, the most important tool at your disposal as a Planner or Scheduler is your software’s ability to sort, group and filter your data set. Because sorting, grouping and filtering allows you to organize the data and cut out the clutter to see only what you need. So, there’s much less of a chance of missing the WOs you need as you’re building your schedule.

It is by far my favorite feature of any Planning and Scheduling tool and I think the absence of such features clearly gives away which solutions weren’t built with the real needs of Planners and Schedulers in mind.

The Maintenance Planning and Scheduling features you want

When I scheduled at NASA, Location and Asset were some of the most commonly used fields we worked with. Additionally, we broke our Labor down into Shops, each of which had multiple Crafts. I look back now (having been training other maintenance Planning and Scheduling teams on AKWIRE [now Prometheus Routine Maintenance] for the last few years) and I think, “I so wish I’d had the ability to sort, group and filter back then!”

The ability to group and filter by Asset, Location, Work Type, or Craft, would have been the ultimate time-saver in creating my schedules. Not to mention, it would have made the scheduled work itself more efficient, by empowering me to make more strategic, thoughtful scheduling decisions.

One of the simplest ways sorting, grouping and filtering would have helped us increase wrench time and decreased wasted time would have been the ability to filter by Location. It would have been that much simpler for me to see all the WOs at any one location, and save the technicians’ travel time by sending them out to complete multiple WOs at the same location. Killing two – or three, or four – birds with one stone: that’s music to everyone’s ears.

How powerful are your Planning and Scheduling tools?

Whether you’re a Planner, a Scheduler, a maintenance manager, or even the CFO or CEO of an organization; optimal Planning and Scheduling is ultimately going to save your maintenance technicians’ time; therefore save your business money and drive better results. You’ve got to ask yourself: how powerful and how effective are the sorting, grouping and filtering capabilities of my Planning and Scheduling solution?

And if the answer is “non-existent” or “not enough”, then I hope I’ve made the case for finding the right tools – ones with powerful grouping and filtering capabilities that will enable your Planners and Schedulers to achieve the results you want.