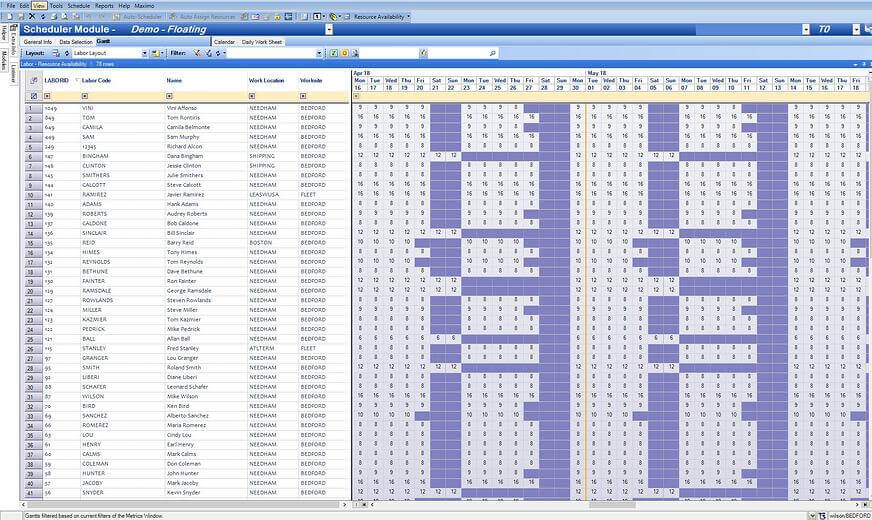

During a recent AKWIRE training class, I was able to listen to an interesting conversation. A Scheduler was explaining her process to validate the level-loading each of the different crafts to two newly hired scheduling colleagues.

Because some of their Job Plans had not been changed since they went live with IBM Maximo, many of the work orders that generate from the Preventive Maintenance (PM) cron task allotted too much time for the work to be performed. Ideally, the long-term fix would be to adjust these Job Plans accordingly, but with multiple Maximo projects being worked simultaneously, this option was not an easy one to accomplish.

So, she and the team thought the best short-term solution would be to schedule 12 of their unique crafts (including 100+ resources) at 120% availability rather than a typical 100%. This would ensure that the maintenance technicians would know which work orders to tackle next if they finished their work for the day/week early.

In their industry, work orders are heavily dependent upon multiple crafts, permits, materials, predecessor work orders, and more. It is far from ideal to have resources in the field pick which unscheduled work orders to perform if they’ve finished their other work early. Scheduling the right amount of work is crucial to ensure everything executes smoothly.

Scheduling a craft at 120%: easy, right?

It’s not rocket science to schedule a craft at 120%. In fact, the math should be relatively simple.

Well, let's look at that. For quick and easy math, let's say we have 10 electricians working a standard 5/8 (five days a week, eight hours a day) schedule. For each day, we've got 96 hours of electrical availability (10x8x1.2=96). Not too bad right?

But how often are things that easy? Let's factor in 100+ resources across seven different shifts, varying Availability Factors, different shift start dates, and numerous time off exceptions (e.g. sick, vacation, training, etc.). Needless to say, what started off as a “simple” math problem, just got exponentially more complicated.

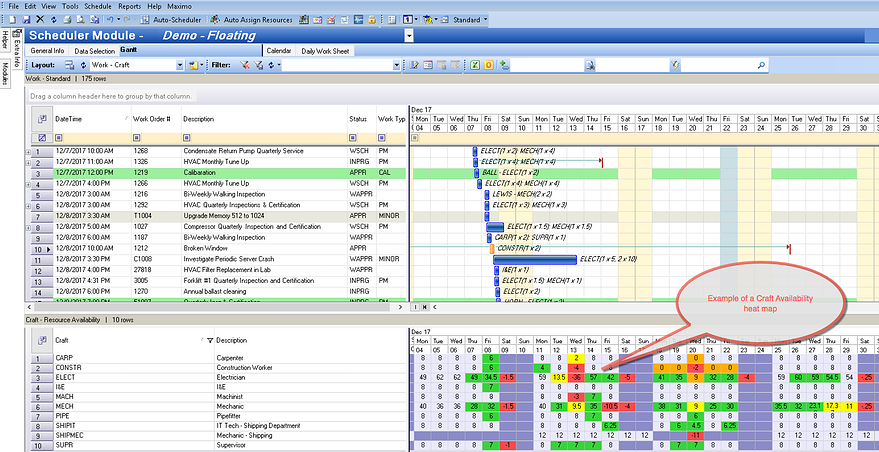

The Scheduler knew that AKWIRE can easily accommodate configuring the Craft Availability heat map (sometimes referred to as Resource Availability) to calculate 120% as fully utilized.

Example: If a technician works 10 hours a day, 120% would reflect their total working hours for that day as 12 hours. When a resource (craft or labor) is fully loaded, AKWIRE will display the appropriate cell for that day with an orange background color and a 0 as the number of available hours.

For this particular customer, AKWIRE is a shared application across different sites, and changing the behavior of the heatmap globally is not desired for all sites. So that option wasn’t available to her.

So, her working solution evolved into multiple exports to Excel, formulas and calculations, and manual validation – all so that she could ensure each craft was appropriately resource leveled. It was a ton of work for this Scheduler.

Previously, she had attempted to increase Maximo's Availability Factor to 1.2 (equivalent to 120%), which is commonly updated from AKWIRE; however, Maximo's architecture won't allow this column's value to exceed 1.0.

As the Senior Scheduler is explaining all this to her new colleagues, I heard her say, “If anyone has an idea on how to make this process easier, please feel free to speak up!”

This was a plea for help to make this process less complicated and more efficient. This was the first I had heard of this situation, and I had an idea.

Flexible tools allow for a 5-minute solution

AKWIRE has the ability to dynamically set the Availability Factor based on a configurable query. Within five minutes, we were able to adjust the Availability Factor for the crafts she requested to 1.2.

A quick refresh of the schedule now indicated the desired number of hours of availability, and they could return to using the AKWIRE heat map as it was intended to be used; once you're in the red, you're over-allocated.

That’s when the waterworks started. The Scheduler working through this process on a day-in/day-out basis began to tear up and said, “Oh my gosh! You're going to make me cry! You have no idea how much this is going to help me.”

It's great to know that a bit of out-of-box thinking combined with an extremely configurable tool can make such significant positive impacts on someone's day-to-day work. This solution will save her and her team several hours every week. They know that they still have a bigger issue to tackle eventually: their job plans. We'll be working with them to help get those fixed, and then they can simply reset the availability factor in AKWIRE back to one. But that's a challenge for another day, so stay tuned.

The right tools do the heavy lifting for you

Planners and Schedulers come up against all sorts of challenges for any number of different reasons. Whether it’s scheduling to 120% availability or scheduling to the labor level at the same time as the craft level, the Planning and Scheduling processes often have unique challenges based on their business and industry. They can’t change them; they just have to work through them.

That’s where other solutions tend to be lacking: in handling the challenges. Ask yourself: how do your tools handle the unique needs of your business? How much of your time, effort, and brainpower goes into supporting your application – when your application should be supporting you? Can your solution accommodate quick and powerful configuration changes, or are you constantly required to pay for costly (and time consuming) customizations?

*Disclaimer: No tears were actually shed in the making of this solution.*