There’s no debate about whether accurate master data improves maintenance. However, gathering, cleansing, and then sustaining that data often presents a challenge. That’s why Prometheus Group released Master-Data-as-a-Service (MDaaS) in 2020.

We often hear about master data projects, but MDaaS isn’t a project. It’s a real solution. One that ensures your master data will always be accurate and up to date.

You can read more about the development and methodology used in Prometheus MDaaS here, but we’d like to make sure you know about one of the more exciting capabilities of the solution: the MDaaS Intelligent Mobile Capture app.

Building a complete and holistic view of your assets requires a lot of data. However, even when you’ve got maintenance data, engineering data, spreadsheets, and more, there’s often a gap that can only be filled with field data collection.

That’s why we introduced MDaaS Intelligent Mobile Capture. It’s a mobile app that runs on both iOS and Android, designed to capture information about your assets with minimal effort. In terms of functionality, it’s essentially a camera app that you can use to capture all the required field data on your assets. All you need to do is take photos of equipment tags, and the system will handle the rest.

The mobile portion of the app is standalone, meaning you can use it anywhere, even without a wireless or cellular connection. On the back end, you can plan out a work package that tells the user what assets to walkdown and then the system will give them a list of the equipment they need to find. Essentially, you’re building a script and putting it into the hand of the technician doing the walkdown.

In this article, we will explain how MDaaS Intelligent Mobile Capture streamlines your data collection by allowing you to take photos of your asset tags, capture data without having to enter it, and keep your data secure.

Use MDaaS Intelligent Mobile Capture Just Like a Camera

Interpreting the information found on tags usually requires an engineer. However, the person taking the photos through MDaaS Mobile Capture doesn’t have to interpret any of that information. All they really need to do is take the photos.

This allows you to assign the field data collection task to a junior level staffer that knows your facility really well and knows where to find all the equipment. We’ve found success by putting this app in the hands of both contractors and staff. As long as they know the plant, they’ll get the job done.

The training to use MDaaS Intelligent Mobile Capture app takes about an hour. Immediately after that training is complete, you can send them out to take pictures of nameplates, inspection plates, engineering performance parameters, and so on.

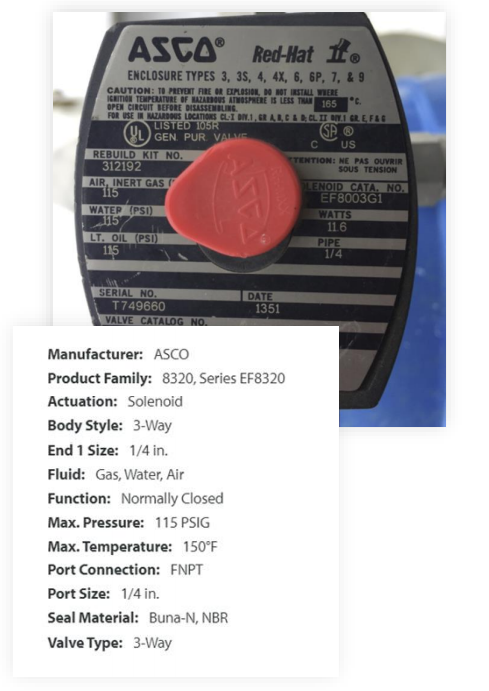

The app will store all these photos locally until the device is back online. At that point, the photos are uploaded and analyzed. The analysis uses a variety of techniques, including optical character recognition (OCR) and image recognition. The system mines the data to build a master equipment list, like the one shown below for a solenoid valve.

You’ll also note an accompanying image of the solenoid valve in question. You might think this image was taken by the marketing department, and you’d be right. The big clue is that it’s clean!

In the real world, tags are rusty, dirty, greasy, or all three. That’s why we trained the app under real-world conditions. If you give it a test, you might be surprised at just what the tool can read, even through layers of grime.

The end result will give you the level of detail you see here, normalized and standardized. These are the mandatory characteristics for a solenoid valve in accordance with ISO 14224.

You can use the MDaaS Intelligent Mobile Capture app to build your master equipment list, but that isn’t all. You can also use it do a walkdown on your MRO (maintenance, repair, and operations) storeroom by capturing photos of packages, labels, and manufacturer model numbers for spare parts. The system will take care of the rest.

Capture Data Without Tedious Data Entry

One of the most exciting aspects of the MDaaS Intelligent Mobile Capture app is that there’s literally no data entry involved. The app will show you what equipment to look for and what types of photos to collect, and all you have to do is take the picture.

From there, we put it together, match the data up with what’s in your system now, and then triage it over to our team of experts. Because the process is so simple, we’re finding that our customers can typically capture information on 200 to 300 pieces of equipment per day.

Building a complete and holistic view of your assets requires a lot of data. You’ve got maintenance data, engineering data, spreadsheets, and more, but there are often still gaps. The app fills in those gaps with field data. Once pulled together and synchronized, all that data from various sources allows us to create a rich as-built picture of your assets.

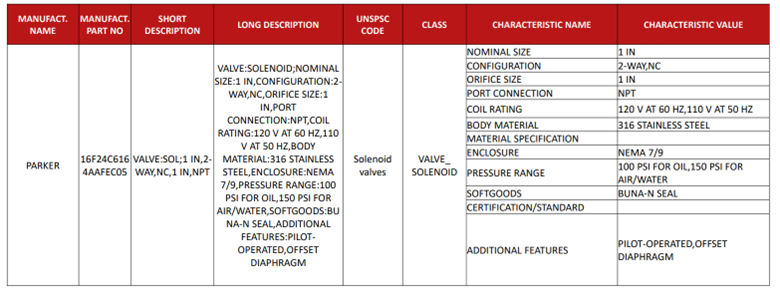

Below you can see a typical record for another solenoid valve. Very often, our customers start the process thinking they don’t have much in the way of good data. The fact is that they usually do have it, it’s all just lumped up in the long text.

We start by mining that long text, recognizing the manufacturer name, model number, and all the characteristics that are correct but in the wrong places. From there, we organize and standardize everything so there's only one correct way to say, "one inch," for example.

Classically, this has been a weakness of maintenance systems. Notes were often hand-written, which often makes them hard to interpret. Even when notes aren’t written by hand, there are endless ways for a busy maintenance technician to abbreviate “one inch,” or for that matter, “solenoid valve.”

The business rules will automatically fill in the information, with only one way to describe it. From there, we auto-generate the short and long text for the equipment record. This ensures that the text descriptions use the correct terms as defined by your master data, and only the correct terms.

Keep Your Data Secure With MDaaS Intelligent Mobile Capture

It can be a challenge to put in a new solution at your organization. One of the advantages of the MDaaS Intelligent Mobile Capture app is that you don’t have to install it on your company’s servers. Technically, it doesn’t even need to go through your organization’s internet. It doesn’t have to touch your IT systems at all. In fact, you can set it up so that it cannot touch your IT system.

With that said, you can implement the solution through your organization’s regular IT channels if that’s what you want to do. Some of our clients do this because they want to be responsible for encrypting the data. However, all the data we gather already goes through our encrypted database.

The photos gathered are used for two purposes. First, they are necessary to build a complete picture of your assets. Second, we use them as part of the machine learning process that continues to improve the system. Your photos and data are never shared with third parties or competitors.

More to the point, the photos taken aren’t of anything that’s proprietary to your organization. These are labels that come from the manufacturer. It’s got nothing to do with your processes, locations, or workflows. It’s about capturing equipment data, not the recipe for your secret sauce.

MDaaS Intelligent Mobile Capture Offers Continuous Improvement

Our vision for MDaaS and this app is for you to be able to hover your camera over a piece of equipment, have the app recognize what it is, and then give you a complete list of spare parts and all the other information you need.

We are starting to reach that level now. When we have a gap, the software goes to the manufacturer’s website and crawls it for the missing information. One of the things it looks for is a spare parts list. We’re getting to an incredible level of detail.

We’re also continually building our equipment library. As part of that library, we’re adding task lists, maintenance plans, bills of materials, and baseline measurement points.

Naturally, MDaaS seamlessly integrates with your other Prometheus solutions. In some ways, this might be the most exciting capability. Asset master data provides the foundation for all improvements, while our planning and scheduling, mobility, analytics, STO, and other tools drive that improvement.

The tight integration means that if you use Prometheus Mobility to create a work order, the data will automatically reflect that. MDaaS keeps your data correct and feeds it into your other Prometheus Group solutions.

More than that, the type of CMMS (Computerized Maintenance Management System) you’re using doesn’t matter. Data is data, and MDaaS is platform-agnostic and integrated with your system or record. Once you approve something on the workflow, it automatically creates the record in your system of record, regardless of whether that’s SAP, IBM Maximo, Oracle, Infor, etc.

Use MDaaS Intelligent Mobile Capture to Gain Control of Your Data

Assets are always changing, and that means that master data sustainment is a challenge that never ends. This is why we often hear master data discussed as a “project.” Over time, once pristine master data becomes corrupted, the process of consolidation, cleansing, and sustainment begins again.

As we noted above, MDaaS follows a different methodology. It’s a solution to the challenge of maintenance master data, not another project. The MDaaS Intelligent Mobile Capture app is a vital part of that solution, providing the field data you need to build a complete picture of your assets.

To learn more about how Prometheus Master-Data-as-a-Service can enhance your maintenance and asset management, contact us today.