Who We Serve

Solutions

Prometheus-AI Platform

Maintenance & Logistics

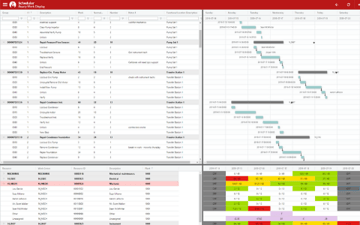

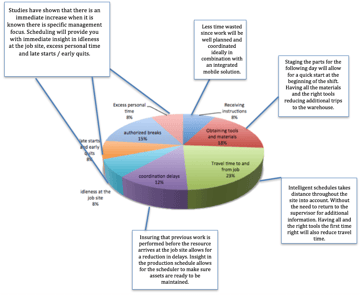

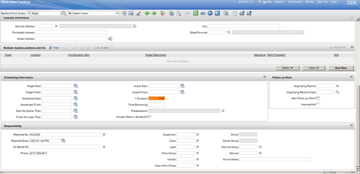

GWOS-AI Planning & Scheduling

RapidAPM Asset Performance Management

STO Manager Shutdown, Turnaround, & Outage

Reporting & Analytics

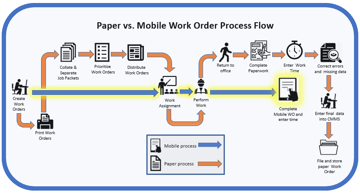

Mobile EAM

Maxavera

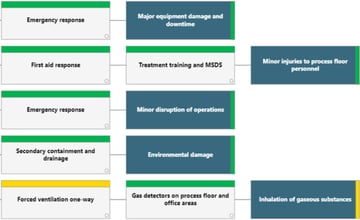

Environmental Health & Safety

RiskPoynt Process Safety Management

ePAS Electronic Permitting

Contractor Management

Resources

Company

.jpg?length=360&name=AU%20headshot%20(2).jpg)

.png?length=360&name=GWOS-AI%201%20(1).png)

.png?length=360&name=62bda4c114222080b62f0482_MicrosoftTeams-image%20(2).png)

.jpeg?length=360&name=AdobeStock_294463480%20(1).jpeg)

-1.png?length=360&name=63592abcd13b8dd105fd2e9a_MicrosoftTeams-image%20(46)-1.png)

-1-1.png?length=360&name=62fcfd4ee43d3b525406ad09_MicrosoftTeams-image%20(21)-1-1.png)

%20Thumbnail%20Image-1.png?length=360&name=63455e83b67d197f36bba77b_5%20Reasons%20for%20Asset%20Failure%20(and%20What%20To%20Do%20About%20Them)%20Thumbnail%20Image-1.png)

-1-1.png?length=360&name=603f953185e011e9f0f9c667_Untitled%20design%20(5)-1-1.png)

%20Business%20Models%20of%20Predictive%20Maintenance-1.png?length=360&name=5d8ba0f9eda39a6ff6e956ca_Thumbnail%20-%20Your%20Quick%20Guide%20to%205%20Maintenance-as-a-Service%20(MaaS)%20Business%20Models%20of%20Predictive%20Maintenance-1.png)

-1.jpeg?length=360&name=5e30b42ce3716850ab1c08b4_Image%204%20-%20small%20(1)-1.jpeg)

-1.png?length=360&name=61a8c97c6a90df654f1224f5_Untitled%20design%20(37)-1.png)

-1.jpeg?length=360&name=5f05be08a047371968b5c83c_AdobeStock_241602252_20%20(1)-1.jpeg)

-1-1.png?length=360&name=62e2812b6d0fc5da88131626_MicrosoftTeams-image%20(13)-1-1.png)

-1.png?length=360&name=60a3f977c2c2372532a4a9ef_Untitled%20design%20(8)-1.png)

-2.png?length=360&name=60534ffa7e13af4929cd2640_Untitled%20design%20(16)-2.png)

-1.png?length=360&name=5d83db9e8b2fc7210d434b79_Thumbnail%20-%20The%20Future%20of%20Maintenance%20Work_%20How%20Will%20the%20Era%20of%20Accelerated%20Change%20Affect%20You_%20(Part%201)-1.png)

-1.png?length=360&name=6048d1d1586136525203429f_Untitled%20design%20(8)-1.png)

-1.png?length=360&name=602c2e772bc4a7bf827d4e4b_Untitled%20design%20(1)-1.png)

-1.png?length=360&name=5d8a37c12198d30715bdf0e1_Thumbnail%20-%20The%20Secret%20to%20Maintenance%20Planning%20and%20Scheduling%20Success%20(It%E2%80%99s%20Not%20What%20You%20Think)-1.png)

%20of%20Enterprise%20Maintenance%20Planning%20and%20Scheduling-1.png?length=360&name=5d8ba406bcdc0a4a4fc0590e_Thumbnail%20-%20The%205%20Ws%20(and%201%20H)%20of%20Enterprise%20Maintenance%20Planning%20and%20Scheduling-1.png)

-1-1.png?length=360&name=5d8a25c9ac6b866e17987fdf_Thumbnail%20-%20The%2012%20Days%20of%20Time%20Savings_%20Planning%20&%20Scheduling%20Features%20That%20Help%20You%20Work%20Faster%20(Part%201)-1-1.png)

-1.png?length=360&name=605b34c28cee48dbe00eabd8_Untitled%20design%20(5)-1.png)

.png?length=360&name=Four%20Types%20Analytics%20(1).png)

-1.png?length=360&name=5d8a2889f24d2f2769792f1e_Thumbnail%20-%20The%2012%20Days%20of%20Time%20Savings_%20Planning%20&%20Scheduling%20Features%20That%20Help%20You%20Work%20Faster%20(Part%202)-1.png)

-1.png?length=360&name=62ebe36c813006da23a71690_MicrosoftTeams-image%20(16)-1.png)

-1.png?length=360&name=5fad5a99770470543ffcc6a0_Cor%20Spotlight-Thumbnail%20(1)-1.png)

-1.png?length=360&name=5d83dcdce6a75339e0f18e4e_Thumbnail%20-%20The%20Future%20of%20Maintenance%20Work_%20Tips%20to%20Thrive%20in%20the%20Era%20of%20Accelerated%20Change%20(Part%202)-1.png)

-1.png?length=360&name=5d8bd87d465c025888a6260c_Thumbnail%20-%20Why%20Maintenance%20Planning%20&%20Scheduling%20should%20be%20a%20Key%20Initiative%20within%20your%20Organization%20(INFOGRAPHIC)-1.png)

-1-1.png?length=360&name=5d84dd984e26fb033982cc44_Thumbnail%20-%20Quality%20Management%20101_%20Maintenance%20for%20Quality%20in%20the%20Era%20of%20Digitization%20(Part%202)-1-1.png)

-1-1.png?length=360&name=5ef4eed86e9bca7066cf6393_Thumbnail%20-%20IIoT%20In%20Maintenance%20And%20The%20Rise%20of%20Digital%20Twins%20(1)-1-1.png)

-1.png?length=360&name=5d84d9dca21fc84280375dc4_Thumbnail%20-%20Quality%20Management%20101_%20An%20Enterprise%20Maintenance%20Professional%E2%80%99s%20Guide%20(Part%201)-1.png)

%20is%20set%20to%20Disrupt%20Enterprise%20Maintenance-1-1.png?length=360&name=5d7fdc45a7e6182ba7ab5331_Thumbnail%20-%20Maintenance-as-a-Service%20(MaaS)%20is%20set%20to%20Disrupt%20Enterprise%20Maintenance-1-1.png)

%20Jobs%20Are-1-1.png?length=360&name=5d77fd73c494dd2a7a01226f_Thumbnail%20-%20Where%20the%20Future%20Maintenance%20and%20Repair%20Operations%20(MRO)%20Jobs%20Are-1-1.png)

-1-1.png?length=360&name=62d823ab17d6f1557e4a7ad5_MicrosoftTeams-image%20(12)-1-1.png)

-1.png?length=360&name=61b215515f1cda38bca93e67_Raul%20Ma%20(1)-1.png)

-1.png?length=360&name=609aec267c9ce9344835b527_Untitled%20design%20(7)-1.png)

-1-1.png?length=360&name=60b7dbfaf9610c853ab09060_Untitled%20design%20(13)-1-1.png)

-1.png?length=360&name=615df9549405ae0523e08a43_Untitled%20design%20(16)-1.png)

-1.png?length=360&name=61e820d493c1c764266a7571_Untitled%20design%20(47)-1.png)

-1-2.png?length=360&name=61e07245733ea2c2637f063b_Untitled%20design%20(44)-1-2.png)

-1.png?length=360&name=62c5f85574232e4e4ee603a8_MicrosoftTeams-image%20(4)-1.png)

-1.png?length=360&name=61d73d84d3b48faf5c110ba4_Untitled%20design%20(42)-1.png)

-1-1.png?length=360&name=62165619eaffe681e1ed035e_S&V%20Cobranded%20Logo%20(blog%20thumb)-1-1.png)

-1-1.png?length=360&name=62bda4c114222080b62f0482_MicrosoftTeams-image%20(2)-1-1.png)

-1.png?length=360&name=6182eb66d3ec51316c7e5f17_Untitled%20design%20(28)-1.png)

-1.png?length=360&name=619659900ffe971f1fba8c96_Untitled%20design%20(33)-1.png)

-1.png?length=360&name=618c3238c0e8833ffef1bc44_Untitled%20design%20(30)-1.png)

-1.png?length=360&name=61a78d3f1434e9bdc3f34b4b_Untitled%20design%20(35)-1.png)

-1.png?length=360&name=62615ed42d8afec43077fcf7_LUCY%20Cobranded%20Logo%20(blog%20thumb)-1.png)

-1.png?length=360&name=5d287981a66e810a3a00826d_Thumbnail%20-5%20Key%20Concepts%20to%20Better%20Understand%20Reliability%20Centered%20Maintenance%20(RCM)-1.png)

-1.png?length=360&name=6036a8c24fd3d57925f177ce_Untitled%20design%20(3)-1.png)

-1-1.png?length=360&name=5f05bf3ddbb1a0749e03acf7_Thumbnail%20-%20Why%20Implement%20an%20ERP%20Connected%20Mobile%20Solution_%20(2)-1-1.png)

%20Maximo%20Work%20Order%20Left%20Behind-1.png?length=360&name=5d7ba08363a9069abae227ba_Thumbnail%20-%20Love%20the%20Way%20You%20Filter_%20No%20Child%20(or%20Task)%20Maximo%20Work%20Order%20Left%20Behind-1.png)